The Role of Digitization in the Printing Industry

Why Innovation Matters

Innovation is the backbone of any business, especially in industries like printing, where staying ahead of the competition is vital. Digital technologies like the Internet of Things (IoT), artificial intelligence (AI), and advanced analytics are transforming the manufacturing landscape. The printing industry, like many others, must embrace these technologies to remain competitive and meet the evolving demands of the market.

Digitization vs. Digital Transformation

While digitization refers to the adoption of digital tools to improve specific business functions, digital transformation encompasses a more holistic shift in how organizations operate. Digital transformation requires not only the application of digital technologies but also organizational change. It involves a customer-centric approach, which becomes the core of business strategies.

For printing businesses, this means automating processes, optimizing workflows, and improving overall efficiency through digital solutions. Automation, in particular, allows businesses to perform tasks more quickly and with fewer errors, increasing productivity and profitability.

Digital Transformation in the Printing Industry

Digital transformation in the printing industry focuses on improving production processes and business models through technologies that enhance speed, efficiency, flexibility, and quality. For this transformation to be effective, businesses must first upgrade their production technologies.

Organizational Changes and Leadership

After technological improvements, companies must also adapt their management practices and organizational structures. Top management must support the transformation and create an environment that encourages innovation. This leadership is key to overcoming employee resistance and ensuring the success of digitalization.

By integrating digital tools and fostering a culture of innovation, businesses can drive efficiency and stay competitive in a rapidly evolving industry.

Product Development

In product development, the ability to quickly adapt to customer needs is crucial. Accurate and timely understanding of these needs, along with the ability to rapidly develop and launch suitable products, is key to success. To achieve this, companies can leverage big data and analytics, allowing them to gain deeper insights into customer preferences and trends.

A great example of this is Peugeot’s car design competition, which not only promoted their brand but also provided valuable insights into customer design expectations before launching new products.

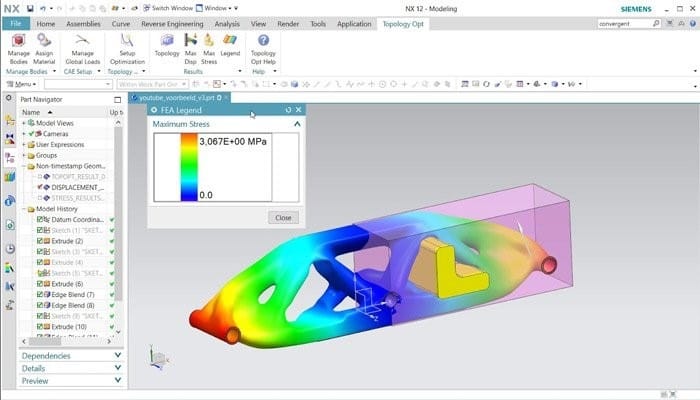

Advancements in Product Design Software

A large number of advanced software in product design facilitates the simultaneous implementation of product development stages. By using these tools, production feasibility can be assessed early in the development phase, saving significant time. Additionally, prototypes created with 3D printers can be visually tested using simulation software. This allows for topological optimization, preparing, visualizing, and reproducing parts for printing.

For example, Ford established an additive manufacturing laboratory, enabling faster and more cost-effective prototype production. As a result, the development time for parts was reduced from days to hours, providing more opportunities to test and refine ideas in less time.

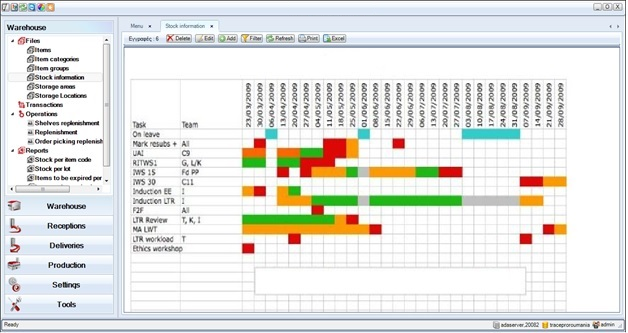

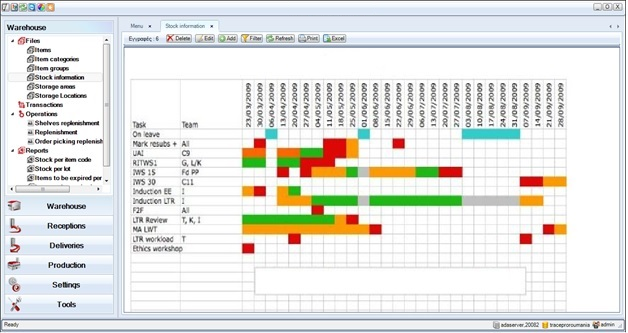

Planning

The most important part of the planning phase is the accurate forecasting of demand. However, in terms of the efficiency and profitability of the enterprise, it is of great importance to plan the production and raw material supply according to this estimate and to optimize it in order to minimize the costs. With each passing day, customers are demanding more variety and more personalized orders, making this very difficult.

To address this challenge, big data and advanced analytical methods, along with planning software consisting of customizable modules, offer significant advantages. These tools provide convenience in both the planning and optimization of supply and production processes. As a result, businesses can save time, reduce errors, and better meet the needs of their customers.

Supply Chain and Logistics

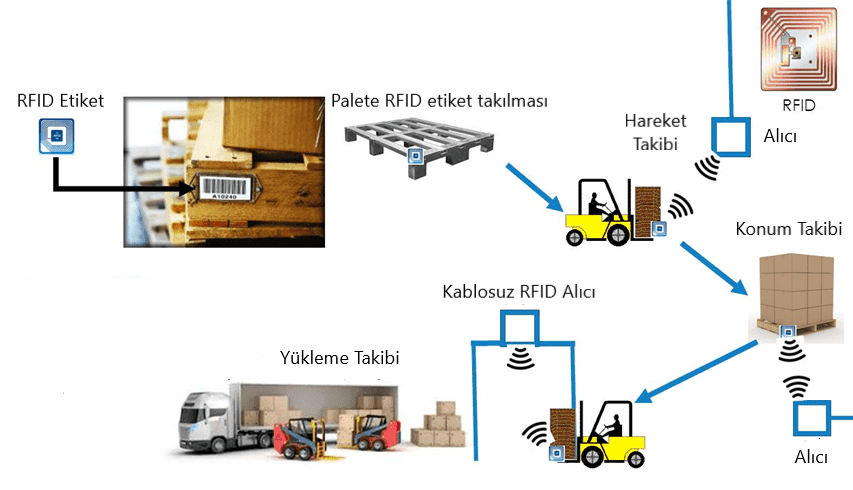

Digital technologies help reduce unnecessary costs and prevent overstocking in supply chain and logistics management. Digital transformation in the printing industry allows businesses to place and receive orders on time while tracking stock levels in real time. This optimization leads to better inventory management and improved operational efficiency.

Real-time inventory tracking reduces labor costs and minimizes errors. RFID tag technology, a key enabler of this transformation, is widely used in warehouse and shipment automation. Businesses can track product quantities, monitor their location in the warehouse, and ensure shipment accuracy with RFID.

Furthermore, RFID technology equipped on transportation vehicles enhances the efficiency of product placement and retrieval in the warehouse. This digital transformation boosts logistics efficiency and helps reduce costs across the supply chain in the printing industry.

Production

Thanks to automation in production, businesses can track and monitor production factors, such as machinery and workforce, which helps prevent errors. Additionally, quality control plays a crucial role in increasing productivity. In the context of digital transformation in the printing industry, businesses can enhance automation by integrating smart systems like advanced robots, real-time monitoring of production factors, and providing instant feedback. This enables businesses to implement automatic real-time quality control, improve root cause analysis, and carry out preventive maintenance to detect malfunctions before they occur, thereby reducing machine downtime.

Furthermore, RFID tags and artificial intelligence with image processing are commonly used technologies in production and quality control. For instance, Toyota collects large data and analyzes it with advanced software. This enables the company to quickly identify and resolve issues, fix faulty products instantly, and reduce machine downtime. As a result, businesses can increase production quantities, improve product quality, and cut costs, driving the digital transformation in the printing industry.

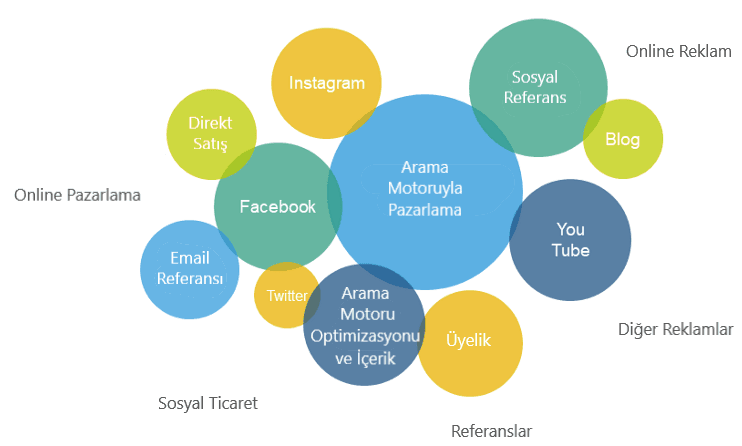

- Sales and Marketing

By leveraging big data and advanced analytical methods, businesses can digitalize their sales and marketing processes, allowing them to efficiently manage customer relationships through various online platforms. As a result, customers can easily access product catalogs, place orders, request consultations, make payments, change order details, track their orders, customize products, and even submit feedback or complaints through the website. Furthermore, businesses can offer personalized promotions and use AI-powered virtual assistants, ensuring customers are engaged at the right time, with the right offer. This contributes to customer satisfaction and strengthens relationships. Additionally, by shortening order processing times, companies can drive sales growth. Furthermore, digital tools help identify potential customers, enhancing the overall digital transformation in the printing industry.

- After Sales Services

Performing periodic, normal, or preventive maintenance on sold products remotely via online connection is a key aspect of the digital transformation in after-sales services. This approach helps shorten machine downtime and reduces maintenance labor and travel costs. Additionally, businesses can utilize tools such as real-time tracking of after-sales service requests, digital customer training, and advanced analytics to provide optimized scheduled maintenance services. Virtual guided maintenance services for products can further enhance efficiency. All these advancements contribute to improving the overall customer experience and drive the ongoing digital transformation in the printing industry.

*Our article in the Printing Sector, digital translation numbered 115, has been published in the Printing Magazine published by the Printing Industry Education Foundation (BASEV).

REFERENCES

[1] The Business Research Company, “Global Printing Market Data And Industry Growth Analysis”, Print Global Market Report 2021, 2021. [Online]. Available: https://www.thebusinessresearchcompany.com/report/printing-global-market-report-2020-30-covid-19-impact-and-recovery. [Accessed on 25-December-2021].

[2] T.R. MINISTRY OF SCIENCE, INDUSTRY AND TECHNOLOGY, “Digital Transformation Report and Roadmap of Manufacturing Industry,” 2016.

[3] Peugeot, “The Flux Winner of the Peugeot Design Contest.” Peugeot, Paris: Peugeot, 2007.

[4] FORD, “Ford Helps Lightweight and Customize Large-Scale 3D Printing in Mind,” News, 2017. [Online]. Available: https://media.ford.com/content/fordmedia/fna/us/en/news/2017/03/06/ford-tests-large-scale-3d-printing.html. [Accessed on 25-December-2021].

[5] “Internet of Everything”, PLANTS, 2014.