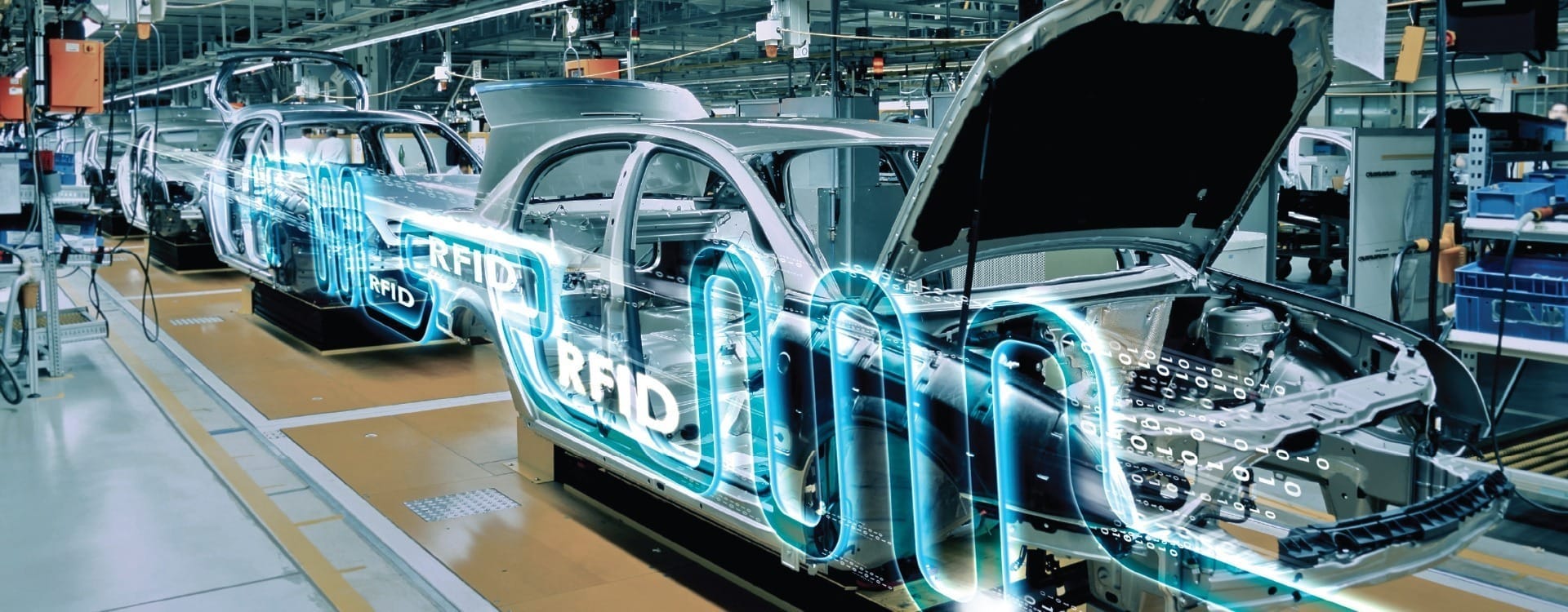

PRODUCTION TRACKING WITH RFID

AUTOMATION

PURPOSE OF THE SYSTEM

In today’s conditions, where efficiency has become the most important factor in achieving success, it has become an inevitable necessity for all companies to use technology in the most effective way to stay one step ahead of the competition. EasyWork production tracking system aims to use time and workforce at every stage of production with minimum loss.

BENEFITS OF THE SYSTEM

- Making Products Individually Traceable

Thanks to the RFID tags placed on the products, each product will have a unique number, such as the serial number, so that it can be tracked at every stage from the beginning to the end of production without being mixed with other products.

- The Label Does Not Need To Be Seen By The Reader To Read The Products.

RFID tags to be affixed to dozens of products stacked on top of each other, side by side or in a box will be able to be read remotely within the scope of RFID Readers.

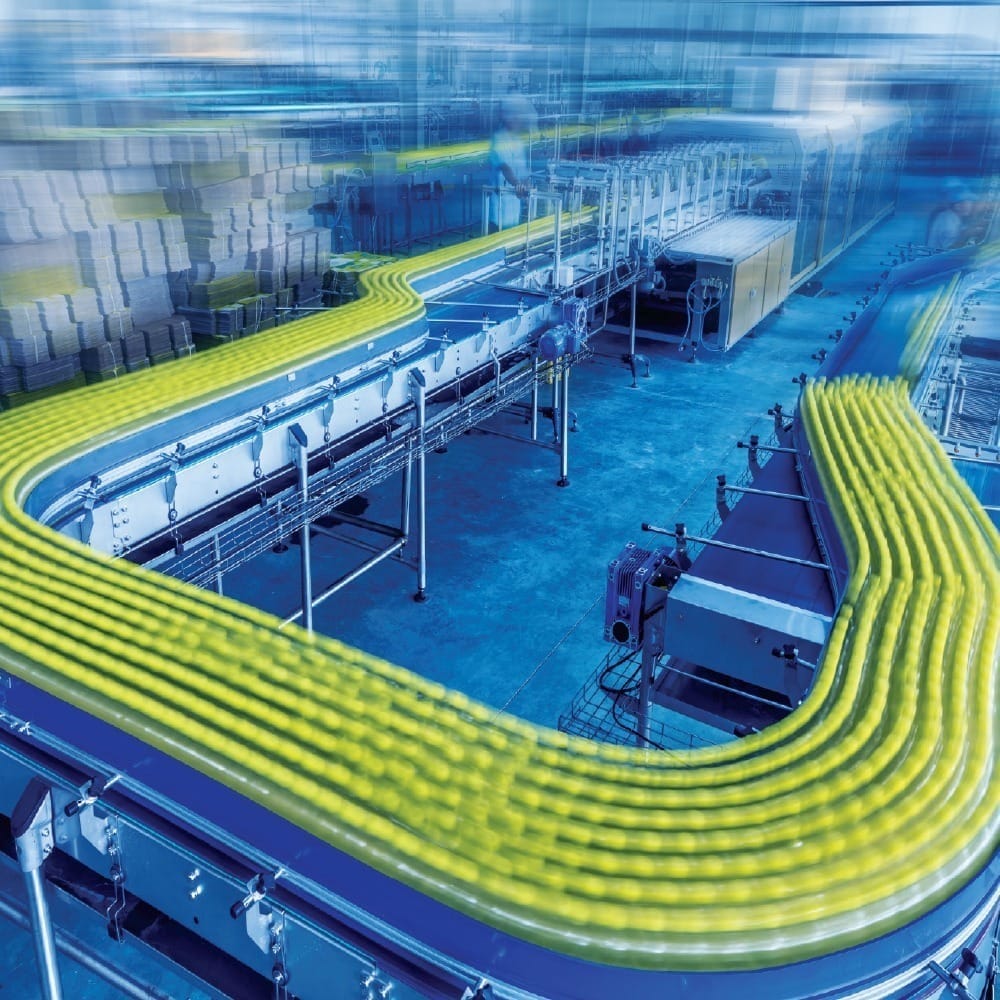

- Instant Multiple Counting Opportunity Instead of Counting One by One

It prevents loss of time during counting and control, as the products can be counted multiple and instantaneously instead of being manually and individually controlled during the displacement of the products.

- Minimizing Human Errors

Removal of the risk of missing or over counting caused by human error and incorrect product entry-exit

- Making Efficiency Measurable Instantly

Thanks to the Readers to be placed on the production lines, the efficiency and instant status of each band can be viewed online.

- Contribution to the Quality Control Process

Thanks to the writable / readable dynamic structure of RFID tags, the information of each product is processed on the labels on them while passing through the bands, thus eliminating the need for a separate workforce for quality control.

Observation of all production stages through a central system

- Contributions to Your Product Shopping with Sub-Industry

Full Control at Every Stage of Production!

Thanks to The System

- Products become traceable one by one.

- The label will not need to be seen by the reader to read the products.

- You will have the possibility of multiple counting instead of counting one by one.

- Man-made errors are minimized.

- Productivity becomes instantly measurable.

- Contribution to your quality control process.

- Contribution is made to your product shopping with the sub-industry.

- Tracking of empty crates and pallets out of production is ensured.