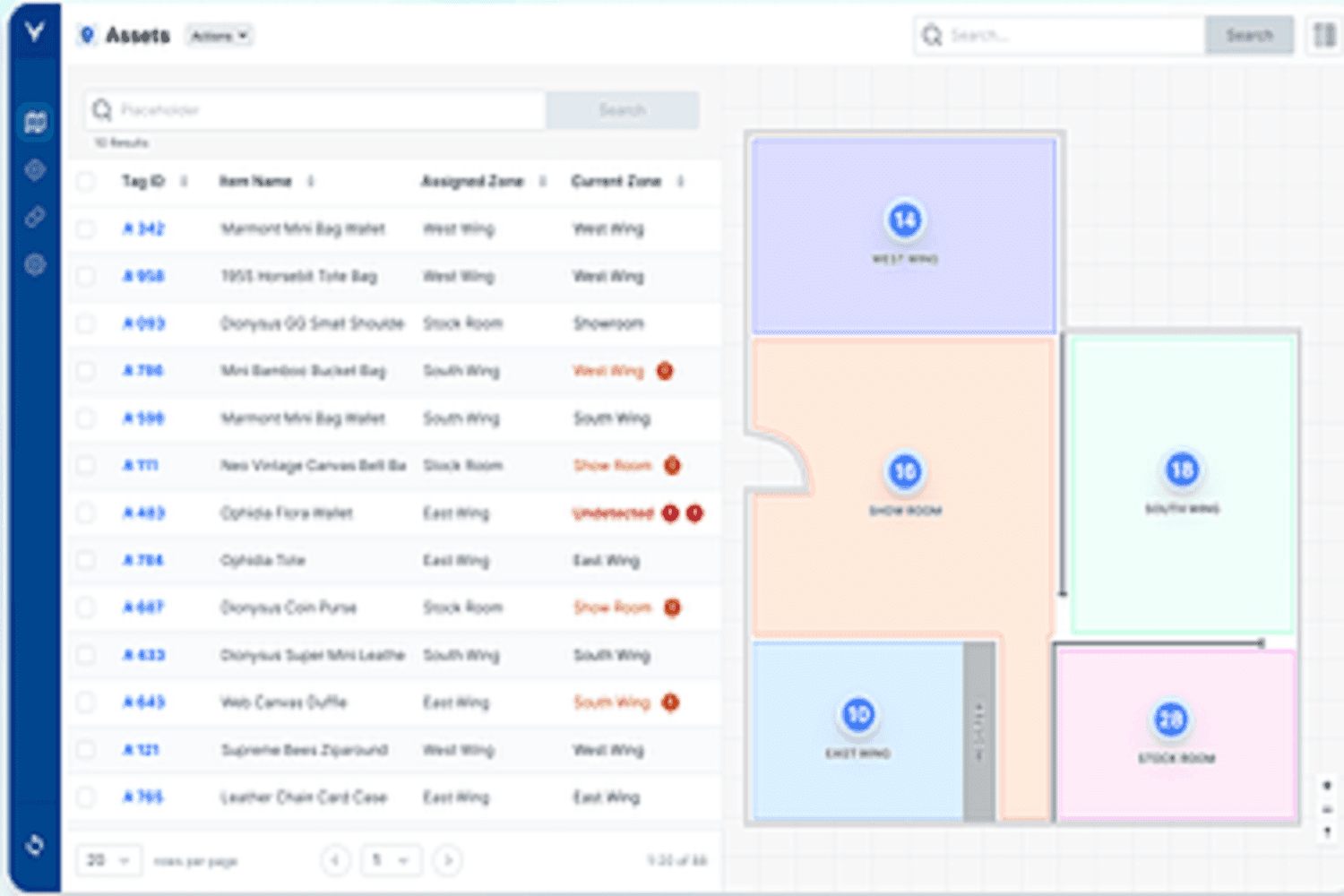

INTELLI WAREHOUSE | RFID WAREHOUSE MANAGEMENT

The Solution that Reduces the Warehouse Counts You Spend Hours on to Seconds!

A technology that does a warehouse count or knows which shelf an item is on in your warehouse.

RFID WAREHOUSE AND SHIPMENT AUTOMATION

Accelerate your operations and optimize your processes with smart automation…

SolutionWarehouse and Logistics Solutions

RFID Warehouse and Shipment Solutions offer an end-to-end automation system that delivers speed, accuracy, and full visibility in warehouse operations. With real-time inventory tracking, product movements within the warehouse are monitored instantly, ensuring maximum process control.

Additionally, RFID enables full automation in critical warehouse processes such as stock management, inventory tracking, inbound/outbound monitoring, loading and unloading operations, and product location tracking. The system easily integrates with existing warehouse software, accelerating workflows and boosting operational efficiency.

With TEKNOPALAS, you make your warehouse and shipment processes smarter, faster, and more reliable.

Features We Offer

Automatic Inventory Tracking and Error-Free Stock Management with RFID

Ensure complete end-to-end product tracking in your warehouse and shipment processes. With our advanced inventory management, you can monitor stock levels in real-time through error-free stock tracking, record product movements, and minimize errors to boost operational efficiency. This allows you to reduce unnecessary inventory costs and respond quickly to customer demands.

Efficient Logistics and Warehouse Management System with Flexible Integration

Optimized Warehouse Space Utilization and Stock Placement Solutions

Maximize the efficiency of your warehouse space. With smart layout planning and warehouse automation solutions, you can strategically position your products to effectively utilize your storage capacity. This approach reduces operational costs while shortening shipment times.

Fast Stock Counting and Real-Time Data Analytics with RFID

Minimize time loss with RFID-based fast stock counting capabilities. Accurately count thousands of items within seconds, dramatically improving your inventory accuracy. By analyzing warehouse and shipment data in real-time, we enable you to make informed decisions and continuously optimize your operational processes. With RFID-supported inventory tracking, all your data is always at your fingertips.

Route Planning and Smart Shipment Optimization

Save time and reduce costs in your shipment processes. Our advanced route planning algorithms identify the shortest and most efficient delivery routes to lower fuel consumption and optimize delivery times. With RFID, you gain full control over your shipments through real-time load tracking and monitoring. Take complete control of all your logistics operations.

End-to-End Warehouse Automation

Provides integrated solutions covering all warehouse processes from goods receipt to shipment dispatch. Continuously updates your inventory with warehouse product counting, stock audits, and lost stock pool tracking. Ensures error-free deliveries through bulk and scattered shipment inspections. Shipment gate passes and packaging operations are tracked automatically. Integration with conveyor systems and other equipment accelerates in-warehouse flow. Maintenance and improvement processes continuously optimize your operations. Quality control steps preserve your product standards. Thus, your warehouse management becomes fully automated and efficient.

Multi-User Remote Access and Control

The system enables multiple users to securely access and control it simultaneously from different locations. It provides role-based permissions for performing operations and viewing data, thereby enhancing operational flexibility and collaboration.

Fast and Automated Order Fulfillment for Efficient Warehouse Management

Deliver your orders to customers on time and accurately. Our RFID-enabled automation and order fulfillment processes eliminate manual errors and optimize picking and packing times. Thanks to RFID readers, ensure the right products match the correct orders. This increases customer satisfaction while helping reduce return rates.

Areas of Use

Food Warehouses

Factories

Stores

Hospital

Pharmacy and Drug Warehouses

E-commerce Warehouses

Automotive Parts Warehouses

Technologies Used

RFID Tags

Customized RFID Tags

RFID Readers

Fixed Readers

RFID Handheld

Mobile RFID Reader

RFID Antennas

Special RFID Antennas for Entry and Exit

RFID Software

RFID Applications

RFID Tag

- RFID tags placed on incoming products or pallets store unique identifiers, stock codes, and critical data. These tags are read quickly and contactlessly by readers, enabling real-time tracking and automatic inventory recording. As a result, shipment processes are accelerated, and accuracy is improved.

RFID Reader

Mobile RFID Reader

- Mobile RFID readers enable fast, flexible scanning of tagged assets without fixed infrastructure. Used in warehouses, vehicles, and field operations, they provide real-time data collection and updates. In smart cities, they ensure high mobility and accuracy for inventory, asset management, security, and logistics.

RFID Antenna

- RFID antennas enable wireless communication between the reader and RFID tags on products or pallets. They use radio waves to quickly and accurately read tags, optimizing data flow and tracking accuracy during warehouse dispatches.

RFID Software

- RFID software used in warehouse and shipment operations enables real-time tracking of product and pallet movements for digital inventory management. It collects data from RFID tags via fixed readers and antennas, centralizing processes such as entry-exit control, location-based placement, automatic stock updates, and shipment verification. As part of a smart city logistics infrastructure, it ensures operational speed, accuracy, and transparency in publicly owned warehouses and distribution centers.

Advantages of the System

Real-Time

The system enables real-time tracking of product locations and warehouse status.

Accurate Counting

Thousands of products are counted quickly and accurately, eliminating human errors.

Fast Counting

Warehouse counting and shipment processes accelerate, workload decreases, and error risk is reduced.

Time Savings

Warehouse and logistics processes are completed in less time, accelerating operations.

Data Analytics

Collected data is analyzed to improve stock and shipment processes.

Real-Time

Accurate Counting

Fast Counting

Time Savings

Data Analytics

Our Content Sources

Accompany your journey

Our Other Solutions

Fast Count System

- Reduced personnel costs

- Store inventory counting becomes easier

- Missing products on shelves are instantly detected

Warehouse Management

- Minimizes human errors.

- Reduces the time to locate required materials.

Personnel Tracking System

- Location tracking of personnel

- A flexible structure enabling the creation of reading points.