MEDARIS | RFID LIBRARY SYSTEMS

Libraries are Smart Thanks to RFID!

By using RFID Library Systems, we ensure that libraries work smart and save time.

RFID LIBRARY SYSTEM

GENERAL FEATURES OF THE SYSTEM

An RFID (Radio Frequency Identification) library system is a technology used by libraries to track and manage the inventory of books and other materials. This technology provides a number of advantages over traditional barcode systems, including improved accuracy and efficiency in tracking materials and greater security against theft.Kütüphanelerde RFID teknolojisinin ana avantajlarından biri, materyalleri kontrol etme ve iade etme ile ilgili süreçlerin çoğunu otomatikleştirme yeteneğidir.

With RFID, library staff no longer need to scan each item individually using a barcode scanner. This can greatly speed up the check-out process and reduce the possibility of errors due to human errors.

It is the solution to the problem of misplacement.

It allows several books to be checked in and out at the same time.

RFID technology can help library staff work more efficiently by automating many routine tasks and providing real-time information about library materials.

Carries out the safe entry and exit of books.

Performs regular book counts.

How does the RFID LIBRARY SYSTEM work?

- RFID Tags: A unique RFID tag or chip is placed on each library item (book, magazine, CD, DVD, etc.). These tags contain the item’s unique ID and related information (e.g., book title, author, ISBN, etc.).

RFID Readers: There are RFID readers located within the library or at various points. These readers detect RFID tags and read the information on the tags.

Book Delivery and Borrowing: Customers bring books to the RFID reader. The reader reads the RFID tag of the book and either removes the book from the inventory or starts the process of lending it to the customer.

Advantages of the System

Real Time Monitoring

Tracks the movement of books in the library. They keep track of which books were checked out when, where and by whom.

Fast Search and Find

RFID tags enable the shelf location of books to be quickly determined. This provides faster service to customers.

Fast Processing

Book borrowing and return processes are faster. Instead of scanning books one by one, a group of books can be read together.

Borrowing Period Monitoring

RFID monitors the checkout times of books and automatically records and helps prevent delays.

Safety Check

It can be used to prevent accidental or unauthorized removal of books and can trigger alarm systems.

Areas of Use

RFID library system is used mainly in libraries, schools, universities and archives.

Sources

OTHER SOLUTIONS

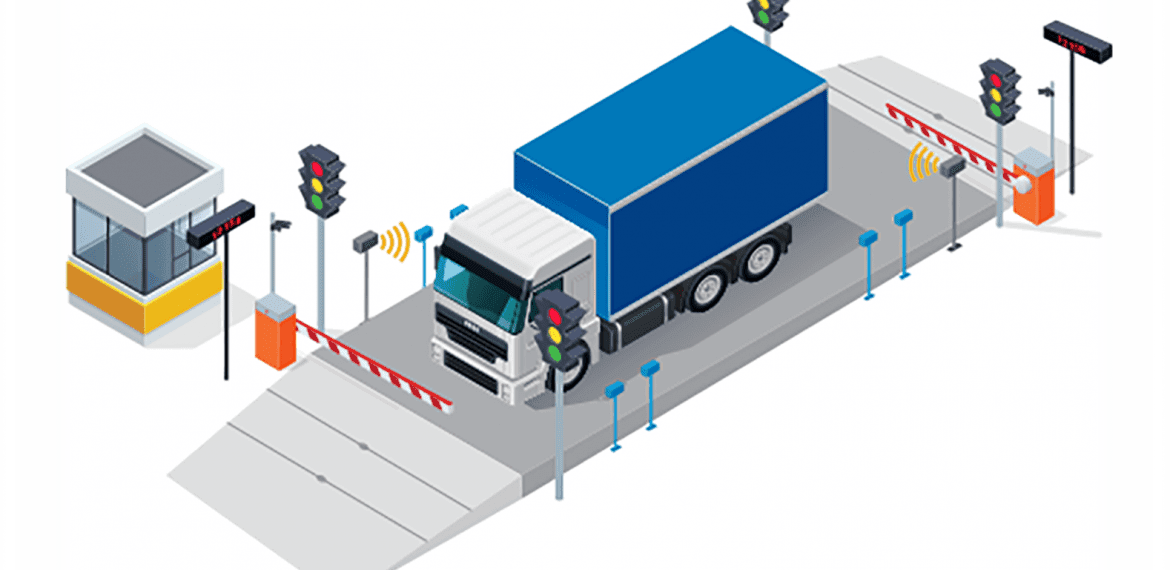

SMART WEIGHBRIDGE SYSTEM

The purpose of the smart weighbridge system is to solve the problems that occur during the tare of the trucks, the weight of the cargo and the exit weighing and to eliminate these problems. Automatic weighing, identification, tracking and administrative reporting of all carrier trucks within the scope of automation can be provided.

Other Content

Keep following us to be informed about all developments in the field of RFID and IoT. New information and new solutions coming soon…

RFID Applications in Automated Weighing Systems

Automated weighing systems are increasingly being used to increase efficiency and reduce the margin of error in industrial processes. One technology that increases the efficiency and accuracy of these systems is Radio Frequency Identification (RFID) technology. In this article, we will examine RFID applications in automated weighing systems and the advantages this technology offers.

Introduction to RFID Technology

RFID technology uses electromagnetic fields to automatically identify and track tags attached to objects. These tags contain electronically stored information that can be read by RFID readers without direct line-of-sight, making the technology versatile and effective in a variety of environments.

1. How RFID Enhances Automated Weighing Systems

Improved Accuracy and Efficiency

RFID technology significantly improves the accuracy of automated weighing systems by eliminating manual input errors and enabling precise data collection. This enables more reliable weight measurements and increases overall operational efficiency by reducing the need for manual intervention.

Real-Time Data Collection

With RFID, data is collected in real time as products pass through the weighing system. This instant data capture allows for immediate processing and analysis, enabling faster decision making and timely response to any discrepancies or issues.

2. Applications in Logistics and Supply Chain Management

Inventory management

In logistics and supply chain management, RFID-integrated weighing systems facilitate efficient inventory tracking. As goods pass through various stages, their weight is automatically recorded and updated in the inventory management system, ensuring accurate stock levels and reducing the risk of overstocking or stock-outs.

Transportation and Shipping

RFID applications in transportation and shipping include automated weighing systems that verify the weight of packages and containers before they are loaded onto transport vehicles. This ensures compliance with weight regulations and optimizes load distribution, improving safety and fuel efficiency.

3. Applications in Manufacturing and Production

Quality control

In manufacturing, RFID-enabled weighing systems play a crucial role in quality control. By continuously monitoring the weight of raw materials and finished products, manufacturers can ensure that each product meets the set weight criteria, reducing the possibility of defects and maintaining high quality standards.

Automatic Sorting and Packing

RFID technology enhances automated sorting and packaging processes by linking weight data with product information. This enables precise sorting by weight and ensures accurate packaging, which is particularly important in industries such as pharmaceutical and food production where precision is critical.

4. Practices in Agriculture and Livestock Management

Crop Yield Measurement

RFID-equipped weighing systems are used in agriculture to accurately measure crop yields. As harvested crops are weighed, data is automatically recorded, helping farmers monitor productivity and make informed decisions on crop management and resource allocation.

Animal Weighing

RFID technology is also used in livestock management to monitor the weight of animals. By attaching RFID tags to livestock, farmers can help effectively monitor animal growth and health by automatically recording weight data during feeding or health checks.

5. Benefits of RFID in Automated Weighing Systems

Enhanced Traceability and Transparency

RFID provides enhanced traceability by linking weight data to specific RFID tags that can contain detailed information about the product or item. This transparency is beneficial for quality assurance, regulatory compliance and customer satisfaction.

Cost Savings and Increased Efficiency

The automation and accuracy brought by RFID technology delivers significant cost savings by reducing labor costs, minimizing errors and streamlining operations. Increased productivity results from faster processing times and reduced downtime.

6. Challenges and Considerations

Integration and Implementation Costs

Despite its advantages, integrating RFID into existing systems can be costly. The initial investment in RFID infrastructure, including tags, readers and software, as well as potential changes to existing processes should be carefully considered.

Data Security and Privacy

With the increasing use of RFID technology, data security and privacy have become critical concerns. Ensuring RFID systems are protected against unauthorized access and data breaches is essential to safeguard sensitive information and maintain trust.

7. RFID and Future Trends in Automated Weighing Systems

Developments in RFID Technology

Continued advances in RFID technology, such as increased read ranges, enhanced data storage capabilities and improved durability of tags, will further expand the applications and effectiveness of RFID in automated weighing systems.

Integration with IoT and Artificial Intelligence

The integration of RFID with the Internet of Things (IoT) and Artificial Intelligence (AI) promises to bring even greater innovation. IoT connectivity enables seamless data sharing between systems, while AI can optimize operations and decision-making by delivering advanced analytics and predictive insights.

Solution

RFID applications in automated weighing systems are transforming industries by providing accurate, real-time data, increasing efficiency and enabling traceability. As technology continues to evolve, the potential for RFID in weighing systems will grow, providing new opportunities for innovation and improvement across a variety of industries.

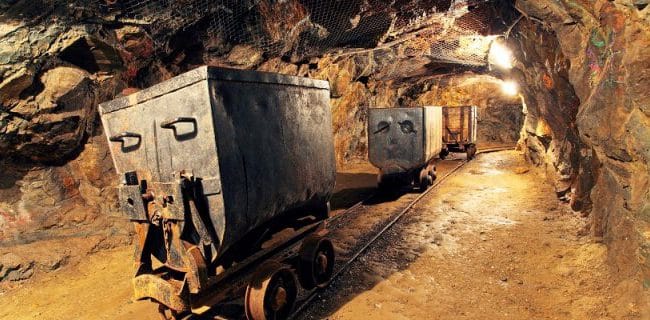

RFID in the Mining Industry

The use of RFID in the mining sector has become increasingly popular in recent years. In this article, we will give you information about how it is used and its application areas. The mining sector has long been a critical component of global economies, providing valuable resources used in various industries and sectors. Recently, RFID in the mining sector has provided numerous benefits and changed the shape of mining operations.

WHAT IS RFID?

RFID is a wireless communication technology that uses radio waves to transfer data between the reader and the tag. Tags are small, durable devices that can be affixed to objects, vehicles or personnel and contain unique identification information. RFID readers are devices that can communicate with and collect data from RFID tags. When an RFID tag enters the range of an RFID reader, the data stored in the tag is transmitted to the reader, enabling real-time tracking and monitoring of assets and personnel.

RFID Applications in the Mining Industry

One of the primary applications for RFID in the mining industry is asset tracking and management. In large mining operations, equipment, vehicles and tools are critical assets that must be tracked and efficiently managed to ensure smooth operations. RFID tags can be attached to these assets, allowing them to be accurately tracked and located in real time. This helps mining companies optimise asset utilisation, reduce equipment downtime and improve maintenance scheduling. RFID technology also enables automated inventory management as tagged items can be automatically scanned and recorded. This eliminates the need for manual counting and reduces human error.

Safety is a top priority in the mining industry and RFID has been instrumental in the development of safety measures. RFID tags can be worn by miners as personal protective equipment (PPE). This enables real-time monitoring of their location and ensures compliance with safety regulations. In the event of a collapse or gas leak, RFID technology can help miners to be found quickly. It can shorten response time and minimise potential damage. RFID-enabled access control systems reduce the risk of accidents by preventing unauthorised access to restricted areas.

RFID is also mainly used in maintenance and repair operations in the mining industry. Equipment maintenance is critical to mining operations, as failures can lead to costly downtime. RFID technology provides real-time data on equipment utilisation, performance and condition. This helps automate maintenance processes. RFID tags can be attached to equipment parts or components. This allows them to be easily identified and tracked. This enables predictive maintenance, where equipment problems can be detected early based on RFID data, allowing timely repair or replacement. This approach enables mining companies to optimise their maintenance programmes.

IW KANTAR Intelli Weighbridge Smart Weighbridge Automation

RFID Scale Automation Purpose

UHF RFID Weighbridge Automation, which was first implemented by Teknopalas in Turkey, enables the weighing of all carrier vehicles, routing, receiving load and driver information, ensuring weighing security, online data transfer to the central system and administrative reporting processes to be carried out unmanned, that is, without the need for an operator.

RFID Weighbridge Automation Features

Security

Stickers affixed to vehicle windows cannot change hands between vehicles. Higgs4 chips, which are accepted by independent test organizations as the world’s best chip with high protection factor against UV light and increased security, which lose their functions when removed from the vehicle glass, are used.

Distance

In the system, the antennas do not need to see the tag, TPS RFID vehicle tags placed on the glass can be detected within the coverage area even if they are not seen by the antennas. This coverage area can be changed between 1-15 meters in line with the needs.

Central Management Module The system is designed to control 10 scales at the same time without delay.

IP Camera

The system can provide IP camera support that can be integrated into every scale at the same time. Weighing records of each vehicle weighed on the scale are matched with video or photo records.

Reportable Photo Recording Module

The moment of weighing is associated with the image values of the vehicle, the driver and the load, allowing visual tracking of past weighings.

Automatic Drive Control

The system reads the driver card of each driver passing through the scale and takes it under control together with the camera recording. Thus, unauthorized shift changes between drivers are taken under control.

Consistency

All data written and read during the 24/7 operation of the system has always managed to be as consistent and reliable as the day it was first installed.

Web Based Reporting

The system allows authorized users to report via internet browsers without the need to install any program.

Durable System

It must have a structure that will continue to operate in all weather conditions and adverse environmental conditions without loss of performance.

Receipt Printing

Labor is saved by eliminating manual data entry.

RFID Weighbridge Automation Working Principle

The vehicle enters the scale. The tare weight information of the vehicle is read and the data is transferred to the main computer. The RFID tag on the vehicle is automatically detected by the RFID reader and the vehicle identification information is read from the screen. The RFID tag of the driver is automatically detected by the RFID reader and the driver information is read from the screen. The RFID software checks the driver and vehicle information from an internal list. If the vehicle and driver information is valid, it reads the weight and stores the weighing record. All stages of the weighing process, start and end information are notified to the driver with relevant messages on the led display. If camera option is added, photos of the vehicle at the time of weighing are saved in the weighing database file.

RFID Weighbridge Automation Usage Areas

Solid Waste Transfer & Storage Centers When the silos arriving at the transfer stations stop on the scale, the license plate information is automatically sent to the central scale automation software and weighing is performed without any user intervention.

How the system works;

– High-security RFID chips are placed in all silos at the transfer stations and in the windows of the transfer vehicles. • RFID reader units on the platforms recognize vehicles approaching the platform.

• Recognition is carried out by chips in vehicle windows, RFID units placed on platforms and control software.

• The RFID system detects that the vehicle parked on the platform has completed its movement and turns the lights of the led panels on the platforms green. The system sends the information of the vehicle approaching the platform to the software.

• When the vehicle filling process is completed and the vehicle starts to leave the platform, the RFID system detects this situation and turns the lights of the led panels red.

Excavation Storage Areas

In the light of science, technology, zoning, urbanization, earthquake and urban transformation issues, the issue of solid waste, especially solid waste and recycling in the urban transformation process, is extremely important in terms of building a healthy environment and sustainable living spaces in our country.

Excavation Waste Measurement-Direction

Automation is the technology that enables the reduction, collection, temporary accumulation, transportation, recovery, utilization and disposal of excavated soil and construction and demolition wastes in a fast and controlled manner without harming the environment.

Waste Paper Collection Centers

Within the scope of automation, weighing and analysis of all scrap paper purchased in an integrated manner with weighbridge automation, tracking and administrative reporting processes can be provided.

Thanks to the RFID tags to be affixed to the windows of all vehicles carrying scrap paper, automatically identified vehicles will be weighed unmanned, and the analysis processes of all scrap paper purchased after the weighing process will be recorded and monitored and controlled.