Blog

TEKNOPALAS RFID&IoTKeep following us to be informed about all developments in the field of RFID and IoT. New information and new solutions coming soon…

RFID Applications in Automated Weighing Systems

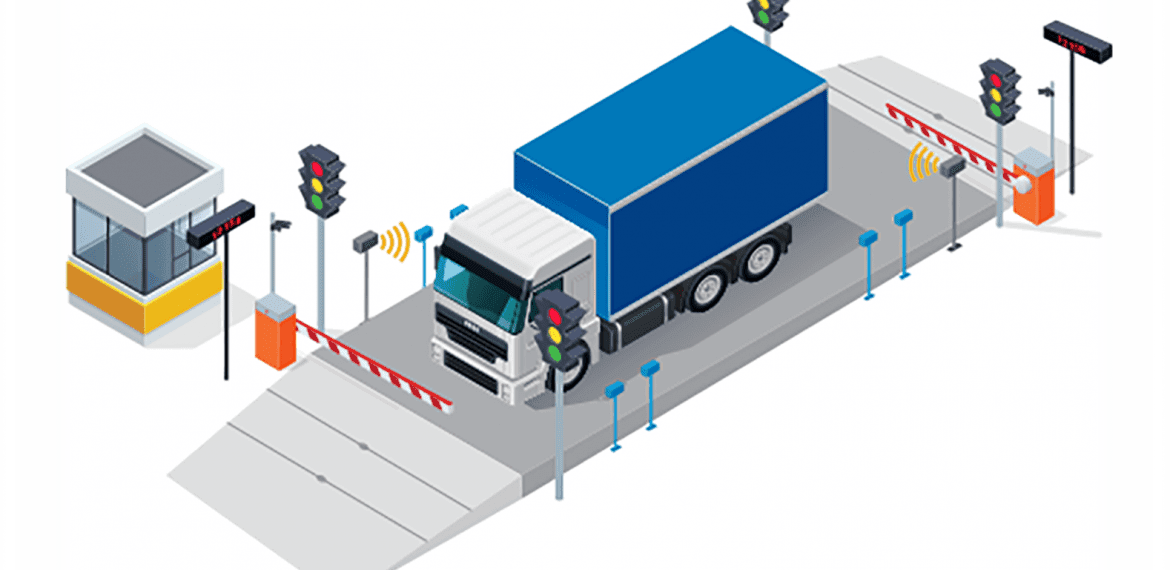

Automated weighing systems are increasingly being used to increase efficiency and reduce the margin of error in industrial processes. One technology that increases the efficiency and accuracy of these systems is Radio Frequency Identification (RFID) technology. In this article, we will examine RFID applications in automated weighing systems and the advantages this technology offers.

Introduction to RFID Technology

RFID technology uses electromagnetic fields to automatically identify and track tags attached to objects. These tags contain electronically stored information that can be read by RFID readers without direct line-of-sight, making the technology versatile and effective in a variety of environments.

1. How RFID Enhances Automated Weighing Systems

Improved Accuracy and Efficiency

RFID technology significantly improves the accuracy of automated weighing systems by eliminating manual input errors and enabling precise data collection. This enables more reliable weight measurements and increases overall operational efficiency by reducing the need for manual intervention.

Real-Time Data Collection

With RFID, data is collected in real time as products pass through the weighing system. This instant data capture allows for immediate processing and analysis, enabling faster decision making and timely response to any discrepancies or issues.

2. Applications in Logistics and Supply Chain Management

Inventory management

In logistics and supply chain management, RFID-integrated weighing systems facilitate efficient inventory tracking. As goods pass through various stages, their weight is automatically recorded and updated in the inventory management system, ensuring accurate stock levels and reducing the risk of overstocking or stock-outs.

Transportation and Shipping

RFID applications in transportation and shipping include automated weighing systems that verify the weight of packages and containers before they are loaded onto transport vehicles. This ensures compliance with weight regulations and optimizes load distribution, improving safety and fuel efficiency.

3. Applications in Manufacturing and Production

Quality control

In manufacturing, RFID-enabled weighing systems play a crucial role in quality control. By continuously monitoring the weight of raw materials and finished products, manufacturers can ensure that each product meets the set weight criteria, reducing the possibility of defects and maintaining high quality standards.

Automatic Sorting and Packing

RFID technology enhances automated sorting and packaging processes by linking weight data with product information. This enables precise sorting by weight and ensures accurate packaging, which is particularly important in industries such as pharmaceutical and food production where precision is critical.

4. Practices in Agriculture and Livestock Management

Crop Yield Measurement

RFID-equipped weighing systems are used in agriculture to accurately measure crop yields. As harvested crops are weighed, data is automatically recorded, helping farmers monitor productivity and make informed decisions on crop management and resource allocation.

Animal Weighing

RFID technology is also used in livestock management to monitor the weight of animals. By attaching RFID tags to livestock, farmers can help effectively monitor animal growth and health by automatically recording weight data during feeding or health checks.

5. Benefits of RFID in Automated Weighing Systems

Enhanced Traceability and Transparency

RFID provides enhanced traceability by linking weight data to specific RFID tags that can contain detailed information about the product or item. This transparency is beneficial for quality assurance, regulatory compliance and customer satisfaction.

Cost Savings and Increased Efficiency

The automation and accuracy brought by RFID technology delivers significant cost savings by reducing labor costs, minimizing errors and streamlining operations. Increased productivity results from faster processing times and reduced downtime.

6. Challenges and Considerations

Integration and Implementation Costs

Despite its advantages, integrating RFID into existing systems can be costly. The initial investment in RFID infrastructure, including tags, readers and software, as well as potential changes to existing processes should be carefully considered.

Data Security and Privacy

With the increasing use of RFID technology, data security and privacy have become critical concerns. Ensuring RFID systems are protected against unauthorized access and data breaches is essential to safeguard sensitive information and maintain trust.

7. RFID and Future Trends in Automated Weighing Systems

Developments in RFID Technology

Continued advances in RFID technology, such as increased read ranges, enhanced data storage capabilities and improved durability of tags, will further expand the applications and effectiveness of RFID in automated weighing systems.

Integration with IoT and Artificial Intelligence

The integration of RFID with the Internet of Things (IoT) and Artificial Intelligence (AI) promises to bring even greater innovation. IoT connectivity enables seamless data sharing between systems, while AI can optimize operations and decision-making by delivering advanced analytics and predictive insights.

Solution

RFID applications in automated weighing systems are transforming industries by providing accurate, real-time data, increasing efficiency and enabling traceability. As technology continues to evolve, the potential for RFID in weighing systems will grow, providing new opportunities for innovation and improvement across a variety of industries.

RFID Smart Production Solutions

In the fast-paced world of manufacturing, productivity is king. Every second counts and every process needs to be optimized to ensure maximum productivity. That’s where RFID smart production solutions come in, revolutionizing the way manufacturing operations are managed and executed. In this article, we explore the transformative power of RFID technology and its role in shaping the future of manufacturing.

Understanding RFID Technology

RFID technology uses radio waves to identify and track objects, assets and products in real time. It consists of tags or labels attached to items, readers or antennas that collect data from these tags, and a back-end system that processes and manages the collected information. Unlike traditional barcodes, RFID tags do not require line-of-sight scanning and can store a wealth of data, making them ideal for a variety of applications in manufacturing.

Advanced Asset Tracking and Management

One of the key benefits of RFID smart production solutions is the ability to accurately track and manage assets throughout the production process. By tagging raw materials, components and finished goods with RFID tags, manufacturers gain real-time visibility into the location and status of their inventory. This visibility enables better inventory management, reduces stockouts, minimizes excess inventory and streamlines the replenishment process.

Streamlined Production Processes

RFID technology also plays an important role in streamlining production processes. By placing RFID tags on work-in-progress (WIP) items and production equipment, manufacturers can monitor the flow of goods through the production line in real time. This allows for better production planning and scheduling, as well as the identification of bottlenecks or inefficiencies that can be addressed to improve overall productivity.

Real Time Information

– know what happened, when it happened and why

Operational Flexibility

– adapt quickly to changing production needs

Flawless Productivity

– holistically manage assets and inventory and scale on demand

Customized solutions

– easily customize data exchanges and workflows

Quality Control and Traceability

Maintaining product quality and ensuring traceability in production is crucial, especially in industries such as automotive, aerospace and pharmaceuticals. RFID smart manufacturing solutions enable manufacturers to implement robust quality control measures by tracking the movement of components and recording production parameters at every stage of the manufacturing process. In the event of a quality issue or product recall, RFID technology facilitates fast and accurate traceability, allowing manufacturers to identify affected products and take appropriate corrective action.

Workforce Optimization

Beyond asset and production management, RFID technology can also be leveraged to optimize workforce productivity. By equipping workers with RFID-enabled badges or wearables, manufacturers can track their movements and activities on the shop floor. This data can be used to analyze workflow patterns, identify opportunities for process improvement and ensure compliance with safety protocols.

Looking to the Future

As technology continues to evolve, the potential applications of RFID smart manufacturing solutions in manufacturing are limitless. Advances in RFID tag miniaturization, sensor integration and data analytics promise to further enhance the capabilities of RFID technology, paving the way for greater efficiency, agility and innovation in manufacturing operations.

As a result, RFID smart production solutions are transforming the manufacturing environment by providing real-time visibility, improving process efficiency, guaranteeing product quality and optimizing workforce productivity. As manufacturers embrace the power of RFID technology, they are poised to gain a competitive advantage in an increasingly complex and dynamic global marketplace.

RFID System Optimizing Rental Vehicle and Equipment Management

In the dynamic environment of rental services, effective management of vehicles and equipment is vital for smooth operations and customer satisfaction. The RFID system, which optimizes the management of rental vehicles and equipment, has led the way by streamlining the processes of systems such as Outline.

Advanced Track and Trace

The Outline RFID system offers a comprehensive solution for tracking and monitoring rental vehicles and equipment in real time. By equipping assets with RFID tags, each item becomes uniquely identifiable, allowing for seamless tracking throughout its lifecycle. This enhanced visibility allows rental companies to precisely locate assets, track usage patterns and prevent loss or theft.

Streamlined Operations

With Outline, rental businesses can streamline their operations by automating various tasks. RFID technology enables automated check-in and check-out processes, eliminating manual procedures and reducing administrative burden. This automation not only saves time, but also minimizes errors, ensuring accurate records of asset movement and availability.

Optimized Asset Utilization

Efficient asset utilization is the cornerstone of profitability in the rental industry. The Outline RFID system enables rental companies to optimize asset utilization by providing insights into usage patterns and demand trends. By analyzing the data collected through RFID tags, businesses can make informed decisions on inventory management, fleet allocation and service planning, maximizing the return on investment for each asset.

Enhanced Customer Experience

A seamless and hassle-free experience is crucial for customer satisfaction in the rental industry. The Outline RFID system contributes to improved customer experience by providing faster and more efficient service. With streamlined processes and accurate tracking, rental companies can fulfill customer requests instantly, minimize waiting times and ensure the availability of the requested vehicle or equipment.

Enhanced Security and Compliance

Security and compliance are critical in rental operations, especially in highly regulated industries such as transportation and construction. The Outline RFID system enhances security by providing tamper-resistant identification and tracking capabilities. In addition, it facilitates compliance with regulatory requirements by keeping detailed records of asset utilization and maintenance history.

As a result, Outline the RFID system that optimizes rental vehicle and equipment management represents a paradigm shift. By leveraging advanced tracking technology, automation and data analytics, rental businesses can optimize operations, improve asset utilization, increase customer satisfaction and ensure compliance with industry standards. With Outline, the future of rental management is smarter, more efficient and safer than ever before.

RFID Tools Tracking

In industries where efficiency, safety and inventory management are paramount, the integration of RFID technology for hand tools tracking is becoming increasingly common. This article explores how RFID tools tracking systems are revolutionizing operations, streamlining workflows and reducing losses.

Efficiency through Automation

RFID tools tracking automates inventory management processes, eliminating the need for manual counting and reducing human error. By attaching RFID tags to tools, each item becomes uniquely identifiable within the system. This allows tools to be quickly and accurately identified, their location and condition tracked throughout their lifecycle.

Real Time Visibility

One of the key advantages of RFID technology is its ability to provide real-time visibility into tool usage and availability. Through RFID readers strategically placed throughout the plant, managers can track the movement of tools in and out of designated areas. This visibility empowers supervisors to optimize tool allocation, avoid unnecessary delays and increase productivity.

Enhanced Security

RFID enhances security by deterring tool tracking, theft and unauthorized use. RFID tags can be programmed to trigger alarms when tools leave designated zones without authorization, helping to prevent loss or misuse. The system also logs all tool movements, allowing discrepancies to be quickly identified and suspicious activity investigated.

Maintenance Optimization

Maintenance programs are critical to ensure tool reliability and extend tool life. RFID tracking systems can be integrated with maintenance management software to automate maintenance alerts based on usage data. By tracking usage patterns and monitoring tool conditions in real time, organizations can implement preventive maintenance strategies and reduce downtime and repair costs.

Enhanced Accountability

With RFID tool tracking, responsibility increases significantly. Each tool is assigned to a specific user or department and its use is recorded accordingly. This accountability encourages responsible behavior among employees, reducing instances of negligence or misconduct. Furthermore, in the event of tool misplacement, RFID technology speeds up the locating process, minimizing disruption to operations.

Conclusion

The incorporation of RFID tool tracking systems into industrial operations offers multifaceted benefits, from improved efficiency and safety to enhanced maintenance practices and accountability. As technology continues to advance, the integration of RFID solutions will likely become standard practice across industries, leading to further optimization and innovation in tool management processes.

Make Your Business Processes Efficient with RFID

In today’s fast-paced business environment, efficiency is key to staying ahead of the competition. One of the technologies revolutionizing operations across various industries is Radio Frequency Identification. Make your business processes efficient with RFID and unlock the most advantages.

Advanced Inventory Management

RFID tags enable real-time tracking of inventory throughout the supply chain. With RFID readers strategically placed in warehouses and distribution centers, businesses can accurately monitor stock levels and locate products quickly. This eliminates the need for manual inventory counts, reducing errors and saving valuable time. What’s more, RFID technology provides insights into inventory movement patterns, allowing businesses to optimize stock levels and minimize excess inventory, thus freeing up capital that can be invested elsewhere.

Optimized Asset Tracking

Lost or misplaced assets can place a significant strain on resources. RFID technology allows businesses to precisely tag and track assets. Whether it’s equipment in a healthcare facility or tools on a construction site, RFID systems provide visibility into the location and condition of assets, minimizing losses and streamlining maintenance processes. This not only minimizes the risk of loss or theft, but also streamlines maintenance processes by facilitating proactive service based on usage patterns and condition monitoring.

Increased Efficiency in Logistics

RFID-enabled logistics operations can streamline processes from shipment to delivery. By tagging packages and pallets with RFID tags, companies can automate tracking and routing, improve accuracy and reduce transportation times. This level of visibility enables better coordination with suppliers and carriers, leading to smoother operations and satisfied customers. In addition, RFID technology enables real-time monitoring of environmental conditions during transportation, ensuring the integrity of sensitive goods such as pharmaceuticals or perishables.

As a result, integrating RFID technology into your processes can lead to significant efficiency gains in your operations. From inventory management to logistics, RFID systems offer a versatile solution to meet the demands of today’s business environment. Embrace RFID and make your business processes efficient with RFID. Move towards greater productivity and success.

RTLS’s Most Common Technologies

RFID technology uses electromagnetic fields to automatically identify and track tags attached to objects. These tags contain electronically stored information that can be read remotely using RFID readers. RFID-based RTLS offers cost-effective solutions for tracking assets in areas such as warehouses or production facilities. It provides accurate location data and integrates seamlessly with existing infrastructure. The most common technologies used by RTLS are listed below.

Bluetooth Low Energy (BLE)

BLE technology enables devices to communicate wirelessly over short distances with minimal power consumption. In addition, BLE-based RTLS solutions are widely used for indoor asset tracking, proximity detection. BLE beacons are deployed throughout the facility to transmit signals collected by receivers and provide real-time location information. This technology is widely adopted in the retail, healthcare and hospitality sectors to improve customer experiences and operational efficiency.

Ultra Wideband (UWB)

UWB technology enables highly accurate indoor positioning by utilizing low-energy pulses to precisely measure the time it takes for signals to travel between devices. RTLS solutions offer centimeter-level accuracy. This makes them suitable for applications that require high precision, such as tracking medical equipment and personnel in the healthcare industry. UWB also performs well in harsh environments with obstacles or interference.

Global Navigation Satellite System (GNSS)

GNSS, which includes GPS, Galileo and GLONASS, provides outdoor positioning capabilities using signals from satellites. Although primarily used for navigation, GNSS integrates into RTLS solutions for outdoor asset tracking and fleet management. It combines GNSS with other technologies such as inertial sensors or cellular networks. It also maintains continuous tracking coverage even in urban canyons or areas with limited satellite visibility.

Wi-Fi Based RTLS

Wi-Fi infrastructure, common in most indoor environments, is also leveraged for RTLS applications. RTLS uses network infrastructure and access points to triangulate the location of Wi-Fi enabled devices. This approach is suitable for asset management in office buildings, retail stores and hospitality venues. It also provides cost-effective monitoring solutions with reasonable accuracy.

As a result, RTLS technologies continue to evolve, providing a variety of solutions to meet the diverse tracking and positioning requirements across industries. RTLS’s most frequently used technologies, whether RFID for warehouse management, BLE for indoor navigation, UWB for precision tracking, GNSS for outdoor logistics, or Wi-Fi for seamless integration. The choice of technology depends on specific use cases, accuracy requirements and environmental factors. As these technologies advance, it is inevitable that the possibilities for real-time tracking and location-aware applications will expand even further, driving efficiency and innovation across industries.