IMPECCABLE CONTROL | PRODUCTION TRACKING SYSTEM

Tracking from Warehouse to Production Line, from Production Line to Shipment is Possible!

RFID technology to automatically track and record various aspects of the production process.

RFID PRODUCTION PROCESS MONITORING SYSTEM

Track every stage of production with RFID, prevent delays, and maximize performance…

SolutionRFID Production Tracking System

Features We Offer

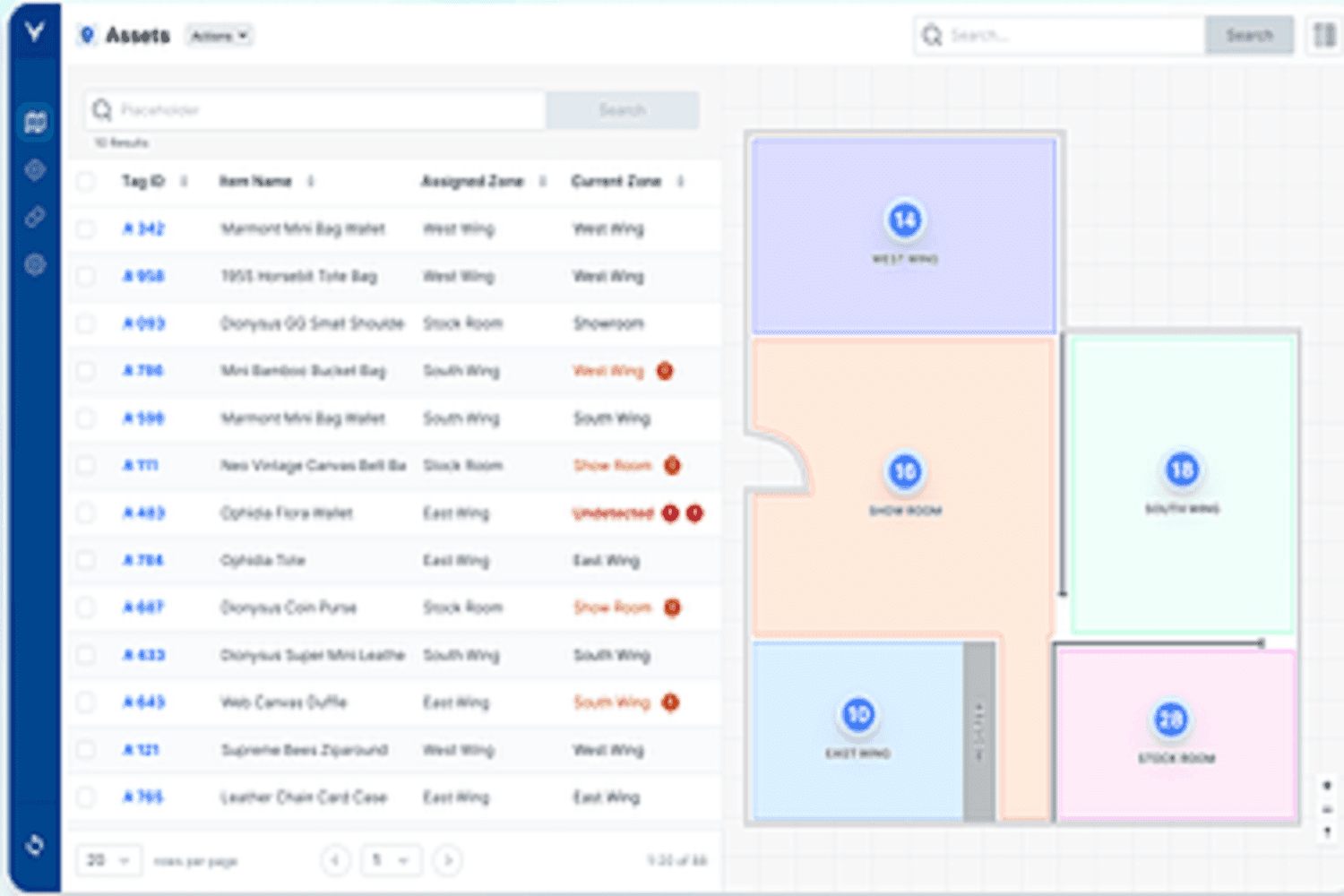

Centralized Production Monitoring

It enables real-time monitoring of all production stages through a centralized system. This way, it becomes clear which process is at which stage on the production line, as well as which products are completed or pending. Centralized management accelerates decision-making processes, allowing potential delays or issues to be detected in advance and addressed proactively.

Eliminating Error Risk

Risks such as undercounts or overcounts, and incorrect product check-ins or check-outs caused by manual counting and data entry are completely eliminated. The system automatically collects and processes all data, saving labor while reducing the error rate to nearly zero.

Product-Based Serial Number Tracking

With RFID tags attached to each product, every item receives a unique serial number. This allows products to be tracked throughout all stages—from production start to packaging, storage, and shipment—without confusion. As a result, risks of loss, mix-ups, or incorrect shipments are eliminated.

Raw Material and By-Product Tracking

Raw materials or partially processed semi-finished products entering the facility can be easily tracked by unit, box, pallet, or container. Incoming and outgoing data are automatically recorded in the system, and stock levels are updated in real time. This ensures there is no excess or shortage of inventory.

Sustainable Production Support

The RFID-based production tracking system optimizes material and energy usage during the manufacturing process. It prevents unnecessary production stops, incorrect material usage, and waste. This not only reduces operational costs but also enhances environmental sustainability.

Real-Time Data Analysis and Reporting

The system collects all data from the production line in real time and presents it on the management dashboard. Information such as production speed, line efficiency, downtime, and fault records is provided through detailed reports, enabling data-driven strategic planning.

Digitization of Quality Control Processes

Each product’s quality control stage in the production process is automatically recorded. Defective products are immediately detected by the system and removed from the production line. This enhances customer satisfaction and reduces return rates.

Areas of Use

Food Warehouses

Factories

Pharmacies and Pharmaceutical Warehouses

Stores

Automotive Parts Warehouses

R&D Centers

Technologies Used

RFID Tags

Customized RFID Tags

RFID Readers

Fixed Readers

RFID Antenna

Application

Data Collection

RFID Tag

RFID Reader

RFID Antenna

RFID antennas and readers installed at critical points on the production line detect and process data from tags attached to products, transmitting it in real time to the production tracking system. This ensures every step of the production process is automatically recorded, eliminating the need for manual data entry and enabling an error-free, efficient manufacturing process.

Data Collection

- As products or components move along the production line, RFID tags are detected by the readers. The reader captures the tag’s unique identification number and other relevant information.

System Advantages

Real-Time Monitoring

It allows products to be tracked at every stage of the supply chain.

Accurate Counting

Automatic RFID reading minimizes data entry errors and ensures more accurate monitoring of production processes.

Security Control

By enabling product tracking, it can reduce the risks of theft and counterfeiting.

Time Savings

It eliminates time-consuming tasks such as manually scanning products or entering handwritten data.

Inventory Management and Tracking

Product check-ins and check-outs are automatically recorded, enabling better management of inventory levels.

Real-Time Monitoring

Accurate Counting

Security Monitoring

Time Efficiency

Inventory Management and Tracking

İçerik Kaynaklarımız

Accompany your journey