INTELLI WEIGHBRIDGE | SMART WEIGHBRIDGE SYSTEM

We Eliminate Weighing Errors with RFID!

We prevent the scale operator from making manual errors and make your scales smart.

TEKNOPALAS RFID Smart Weighbridge Management System

Manage Your Weighing Processes Automatically and Securely…

SolutionRFID Weighbridge Automation

With the unmanned weighbridge tracking system, all carrier trucks (excavation vehicles, garbage trucks, etc.) within the scope of automation can be automatically weighed, identified, tracked, and managed with administrative reporting. Thanks to the RFID TAGs attached to the windshields of all cargo vehicles, automatic identification will become 100% accurate, and the operator-free weighbridge system will eliminate operator dependency.

In the vehicle measurement industry, this feature is one of the fastest-growing areas. Automation systems integrated with solutions such as the weighbridge license plate recognition tracking system, customs-compliant weighbridge tracking system, and similar structures offer businesses a great opportunity to reduce labor costs and increase operational efficiency. By minimizing office staff involvement in weighing processes, personnel can focus on other responsibilities and office activities.

Features We Offer

Fast and Reliable Weighbridge Tracking

Ensures uninterrupted sales during counting. Vehicle weighing data is recorded in real-time with the unmanned weighbridge tracking system. The truck weighbridge tracking system provides fast and error-free data even during intensive field operations.

Customs-Compliant Weighbridge Tracking System Integration

The weighbridge license plate recognition tracking system enables automatic identification of vehicles without the need for manual entry. A customs-compliant weighbridge tracking system is established using multiple technologies such as RFID, QR codes, and barcodes.

Weighing-Based Consumables and Material Management

In material-based operations such as gravel weighbridge tracking systems, weighing results are automatically reflected in consumption records. Material dispatches and stock movements are synchronously monitored within the system.

Operator-Free Weighing Processes and Asset Tracking

Thanks to the operator-free weighbridge system, weighing is performed without driver intervention. At the same time, vehicle, load, and time information are recorded, making the processes accountable.

Weighbridge Maintenance and Calibration Process Tracking

Regular maintenance and calibration scheduling is conducted for unattended weighbridge systems. This ensures system accuracy is maintained and data reliability is enhanced.

API Integration with ERP, Logistics, and Accounting Software

Unmanned and operator-free weighbridge systems integrate directly with existing ERP and third-party software. Thanks to the API infrastructure, weighing data is transmitted in real-time.

Creation of DBA / VGM Document

The system facilitates the creation and tracking of DBA / VGM (Verified Gross Mass) documents. It works fully compatible with the Ministry of Transport’s U-NET system, automating electronic document addition, cancellation, and inquiry processes.

Areas of Use

Factories

Waste Management

OIZ

Logistics

Construction Sites

Food & Agriculture

Excavation Sites

Technologies Used

RFID Tag

RFID Reader

RFID Antenna

LED Display

Sensor

RFID Software

RFID Tag

- The first step is placing RFID tags on the vehicles or loads to be weighed. These tags store the identity information of the vehicle or load along with other relevant data. Each RFID tag has a unique identification number, which is read contactlessly and quickly by sensors in the weighbridge system, ensuring accurate recording of weighing data.

RFID Reader

- RFID readers are devices that detect and process data stored on RFID tags attached to vehicles or products. They receive signals from the tags, decode them, and transmit the information to the weighbridge system to ensure accurate and fast data recording.

RFID Antennas

- RFID antennas are signal transmitting and receiving components that enable wireless communication between the reader and RFID tags. They emit radio waves to facilitate tag reading and optimize data transfer within the reader’s coverage area.

LED Display

- LED displays used in weighbridge systems allow operators and drivers to easily view weighing results. Offering high brightness and clear visibility, these screens display real-time weight data and provide error and warning messages to support fast and accurate operations. Their durable design ensures reliable performance even in challenging field conditions.

Sensor

- Sensors in weighbridge systems detect RFID tags on vehicles contactlessly, enabling accurate and fast data collection. These sensors ensure precise measurements during the weighing process and allow reliable data transmission to the system. With high accuracy and continuous operation, they play a critical role in the automation of weighbridge operations.

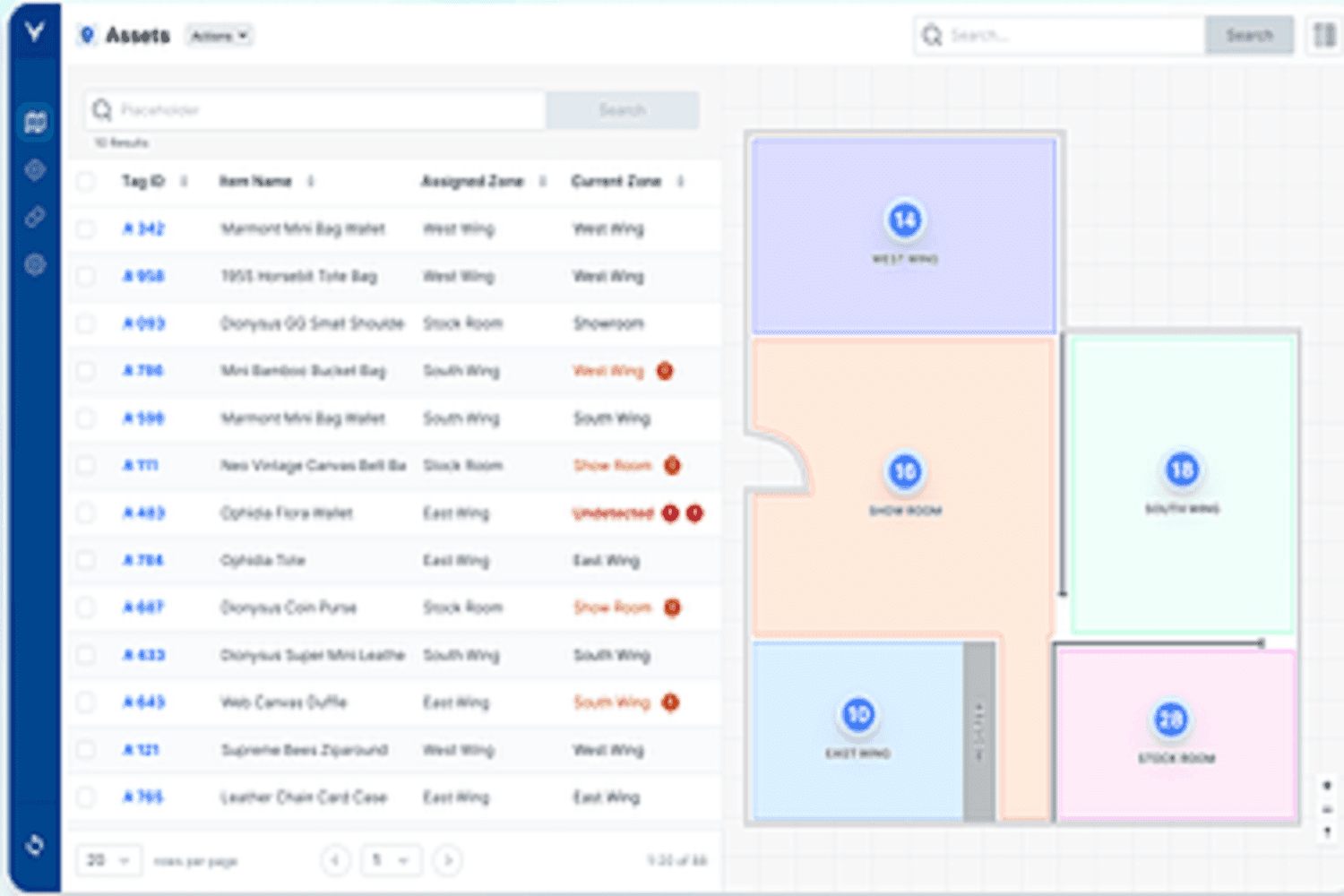

Data Processing and Visualization

- Data collected by the RFID reader is processed by the weighbridge software, and the weighing results are analyzed. The processed data is stored in a central database and made accessible to users. The software enables graphical and tabular visualization of measurement results, making it easier to monitor and report weighbridge operations.

Advantages of the System

100% Automatic

It is a fast system that completely eliminates operator dependency.

Centralized Management

All operations performed across multiple locations can be monitored instantly from a single centralized system.

Accurate and Fast Weighing

It significantly speeds up processes like inventory counting while reducing the risk of human errors.

Time Saving

Time is saved by automating measurement and data collection instead of manual entry.

Data Analytics

Enhanced customer service is provided through multi-option reporting and clear, easy-to-read receipts.

100% Automatic

Centralized Management

Accurate and Fast Weighing

Time Savings

Data Analytics

Our Content Sources

Accompany your journey