Digital Transformation in the Printing Industry

The printing industry market consists of printing services provided by organizations that print products such as newspapers, books, labels, business cards, stationery, business forms and other materials. The growing population globally is the main driver of this market. According to research by The Business Research Company, the global printing market was projected to grow from $277.12 billion in 2020 to $305.34 billion in 2021 at a compound annual growth rate (CAGR) of 10.2% due to the negative impact of the pandemic, but it is expected to reach $366.1 billion in 2022, an increase of 19.9% as everything starts to return to normal [1]. With such a large volume, it has become inevitable for the printing industry to keep up with the developing world and technologies and to start using digital technologies to best meet customer needs. Digitalization is literally the process of using digital technologies and information to transform business operations. Digitalization is now causing major transformations in the business world. Acquiring digital skills is now a prerequisite for individual, sectoral and regional success.

Innovation is the most important rule of business, it is crucial to find technological and innovative solutions that can flexibly face the needs of the market. The tools used in the digitalization of manufacturing industries are digital technologies such as the Internet of Things (IoT), artificial intelligence (AI) and advanced analytics, as well as advanced manufacturing technologies such as robotics and additive manufacturing [2]. Digitalization is one of the key issues that all the different companies in the printing industry need to improve their position. Digitalization in printing processes has been a visible and clear trend for a long time. Perhaps the first step for companies should be to find a hybrid solution, combining all the advantages of digital with traditional technology. In the industry, digitalization and innovation should be a means, not an end. As organizations apply digital technologies in the digitalization process, the way people do their jobs changes. Imagine, for example, if printing press workers stopped individually checking the quality of printed products and instead used computer-controlled equipment. This kind of change is at the heart of digitalization. Whether it is changing job roles or transforming business processes in general, automation is an essential part of the digitalization process. With digitalization in the printing industry, it is possible to increase process efficiency, improve data transparency and, of course, increase profitability. In addition, it makes it possible to produce the same output using fewer people, as it allows many tasks that were previously done by humans in traditional ways to be done autonomously.

But digitalization is quite different from digital transformation. Digital transformation for an organization is not something that businesses can implement as a project. A number of digitization projects need to take place within the business, from automating business processes to retraining employees to use computers. There is a need for customer-centric strategic business transformation that requires organizational change as well as the implementation of digital technologies. When it comes to digital transformation, many companies typically include several digitization projects, but make the big strategic mistake of believing that digital transformation is nothing more than digitization. In reality, digital transformation requires the organization to better cope with change in general, making change a core competency as the organization becomes end-to-end customer-centric. This kind of agility will facilitate ongoing digitalization initiatives. After all, businesses are digitizing information, digitizing the processes and roles that make up their operations, and digitally transforming the business and its strategies. While each is necessary for the next, it is not sufficient. Most importantly, while digitalization is intrinsically about technology, digital transformation is about the customer. In fact, digital transformation is much more than a customer-centric technology transformation. In reality, organizations can achieve end-to-end business transformation if they can identify change as a core competency. The digital transformation roadmap is a complex, interwoven set of steps that businesses must take to achieve the benefits of digital transformation.

Digital transformation in the printing industry basically means that businesses improve their production processes and business models by utilizing applications that increase speed, efficiency, flexibility and quality. In order for this transformation to be efficient, enterprises must first develop the technologies they use in their production processes. Then, they will need to improve their management approach, organize their organizational structure and transform their business culture. In a business, the top management must first embrace the transformation and improve the organizational structure in a way that will allow digital transformation to take place. In addition, there may be resistance to change among employees, and in order to prevent this, they should ensure that a culture of innovation develops among employees. Digitalization supports the creation of a culture where data and analysis are much more effective in the decision process [2].

When we talk about digital transformation, the production process comes to mind first. In fact, in addition to production, companies should also digitalize and integrate administrative processes such as product development, supply chain and logistics management, service delivery, corporate relations, quality management, and sales and marketing.

- Product Development

The most important point in product development is the timely and accurate understanding of customer needs. Another important point is the rapid development and launch of appropriate products. With the help of “big data and analytics”, one of the digital technologies, it is possible to understand customer needs earlier and more accurately. Peugeot’s own car design contest [3] is a good example of this, where Peugeot not only promoted itself but also learned its customers’ design expectations in advance.

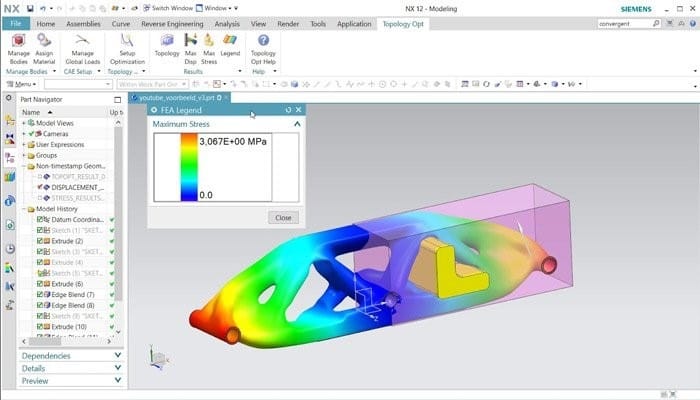

The large number of sophisticated software programs available for product design facilitates the simultaneous realization of the stages of the product development process. By using these software, production feasibility can be made at the beginning of the product development phase and time can be saved considerably. As seen in Figure 1, prototypes to be obtained with 3D printers can be visually tested beforehand by using simulation software. Thus, topological optimization of 3D printing can be done to prepare, visualize and iterate the parts to be printed on the 3D printer. It enables the convergence of traditional geometry with mesh models of the same model. Ford has achieved this very well by setting up an additive manufacturing lab. It was able to make prototypes faster and very cost-effectively, reducing the development time of parts from a few days to a few hours. Thus, it was able to test and refine more ideas in less time [4].

- Planning

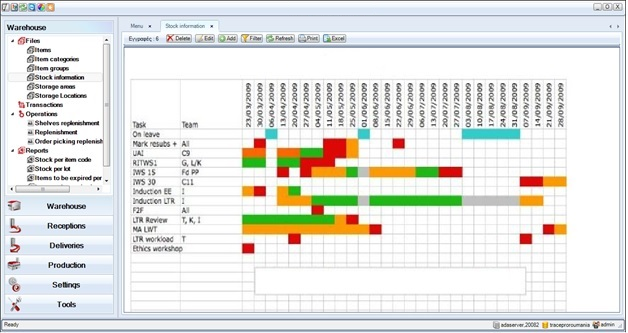

The most important part of the planning phase is the accurate forecasting of demand. However, it is crucial for the efficiency and profitability of the business that production and raw material supply are planned according to this forecast and optimized to minimize costs. This is becoming more and more difficult as customers demand more variety and more personalized orders. Big data and advanced analytical methods, with planning software consisting of modules that can be diversified according to the needs of the business, facilitate the planning and optimization of production as well as supply, saving time and reducing errors.

- Supply Chain and Logistics

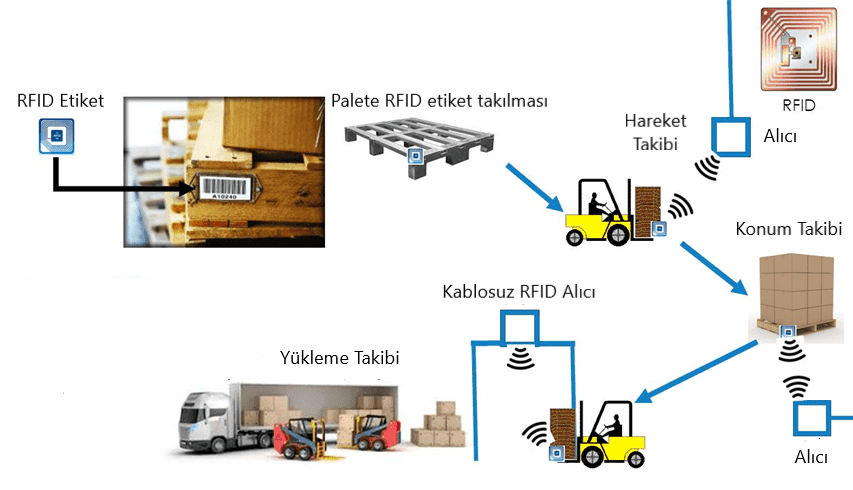

With the use of digital technologies in businesses, unnecessary costs are reduced while preventing excessive stocks in supply chain and logistics management. When digital technologies are used effectively, both orders are placed and received at the right time and in-warehouse inventory tracking can be done in real time. Therefore, errors are minimized while reducing the use of labor in warehouse recording and in and out of warehouse shipments. With RFID tag technology solutions, which have recently been widely used in warehouse and shipment automation, it is possible to track the quantity of products, locate and track them in the warehouse, and check that the shipment is complete and accurate (Figure 3). In fact, when the vehicles used for transportation in the warehouse are also equipped with RFID technology, ease and efficiency can be achieved in product placement and retrieval in the warehouse.

- Production

Thanks to automation in production, tracking and monitoring of production factors such as machinery and labor helps to prevent potential errors, while quality control and monitoring helps to increase productivity. With digital transformation, it is possible to support automation in production with intelligent systems (advanced robots, etc.), provide instant feedback by remotely tracking and monitoring production factors in real time, perform quality control automatically in real time and increase the effectiveness of root cause analysis, and shorten machine downtime with preventive maintenance that can detect failures before they occur. Among the technologies used in production and quality control, RFID tags (Figure 4) and the use of image processing and artificial intelligence are the most widely used. With the software that Toyota has started to use to prevent quality problems in production, it collects and analyzes big data and can instantly track and solve problems and defective products. Thus, it can reduce machine downtime, increase production quantities and product quality, and reduce costs [5].

- Sales and Marketing

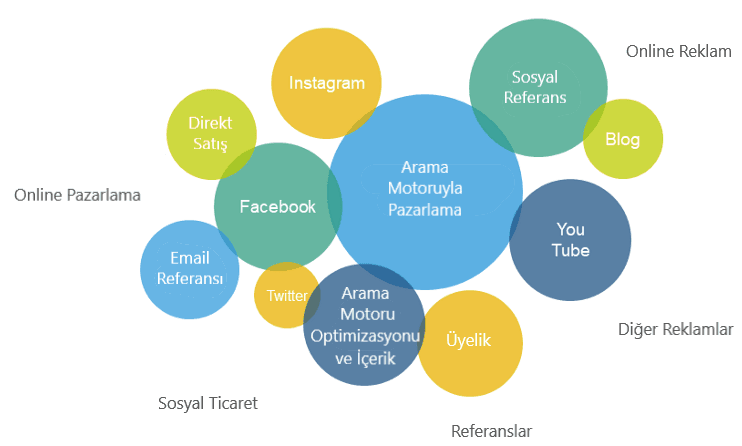

It is possible to utilize big data and advanced analytics methods to digitalize sales and marketing processes for the efficient management of customer relations in businesses by using various online platforms (Figure 5). In this way, customers can access the product catalogue online and place orders, receive consultancy and solutions about the product, make payments, change orders or dates, track their orders, personalize the product they ordered, and report their opinions and complaints on the web page. Businesses can even offer personalized promotions or offers instantly and use virtual assistants with artificial intelligence. Thus, the customer is both reached at the right time in the right way and made happy. While making customer relations sustainable, sales can also increase as order processing times will shorten. In addition, it may also be possible to identify potential customers.

- After Sales Services

Performing periodic normal or preventive maintenance of the products sold by connecting remotely online is part of the digital transformation in after-sales services. In this way, it is possible to shorten the downtime of machines and reduce the costs of maintenance labor and travel. It can also be used to receive and track real-time after-sales service requests, provide customer training digitally, offer scheduled maintenance optimized with advanced analytics for products, and offer virtual guided maintenance for products.

Businesses need to develop new technologies to realize digital transformation, but they need technical and financial support for this. In order to get financial support in this context, they can cooperate with universities to support the introduction of newly developed technologies into their businesses, apply for incentives through government-sponsored R&D projects (TÜBİTAK, KOSGEB, etc.) or cooperate with other companies.

There are three different strategies for companies that want to digitally transform their businesses but don’t know when and where to start;

- You can expect proof of digital success

This first approach will help organizations focus on empirical results. The challenge with this approach is the enormous risk of being idle until your digital transformation catches up. If your competitors achieve digitalization faster than your company, it gives you a distinct advantage. Since most organizations have a mix of digital and non-digital solutions, this first approach is often the first choice for most companies.

- Develop an all-encompassing digital strategy

This approach focuses on completing as much of the strategy as possible from the beginning. It requires a solid, long-term plan. The all-inclusive digital transformation strategy focuses on changing the culture and implementing innovation quickly. It is often a very expensive approach with many pitfalls. It is a method used by businesses with great patience and a willingness to take risks.

- You can realize digitalization in stages

In this approach, a company sets an initial goal and course and then moves towards a potentially changing digital destination. But as the organization progresses, lessons learned and new inputs are taken into account, so that the digital goal, and sometimes the path to the goal, changes. Therefore, this approach focuses on delivering a robust yet malleable strategy that can evolve with industry changes throughout its lifecycle.

Digital transformation in companies in the printing industry varies greatly depending on the specific challenges and demands. But the one constant is that the more technology changes, the more companies will need to adapt. Businesses that pursue digital transformation will benefit from the results and enjoy greater success than those that do not. As a result, to gain strategic advantage in a digitally transformed world, businesses need to be horizontally self-sufficient organizationally across the enterprise, do business fast, be scalable, digitize voluntarily, and leverage smart software and hardware. Digital transformation can be considered as a new industrial revolution for the manufacturing industry. In the coming days, the dynamics and functioning of the manufacturing industry may change thanks to digital transformation, and global balances may change accordingly. The important thing is where you aim to be in this process.

*Our article titled “Digital Transformation in the Printing Sector” was published in the last issue of the Printing World magazine published by the Printing Industry Education Foundation (BASEV) numbered 115.

REFERENCES

[1] The Business Research Company, “Global Printing Market Data And Industry Growth Analysis,” Printing Global Market Report 2021, 2021. [Online]. Available: https://www.thebusinessresearchcompany.com/report/printing-global-market-report-2020-30-covid-19-impact-and-recovery. [Accessed: 25-Dec-2021].

[2] T.C. BİLİM SANAYİ VE TEKNOLOJİ BAKANLIĞI, “İmalat Sanayinin Dijital Dönüşümü Raporu ve Yol Haritası,” 2016.

[3] Peugeot, “The Flux Named Winner of the Peugeot Design Contest.” Peugeot, Paris: Peugeot, 2007.

[4] FORD, “Ford Tests Large-Scale 3D Printing With Light-Weighting and Personalization in Mind,” News, 2017. [Online]. Available: https://media.ford.com/content/fordmedia/fna/us/en/news/2017/03/06/ford-tests-large-scale-3d-printing.html. [Accessed: 25-Dec-2021].

[5] “The Internet of Everything,” PLANT, 2014.