ACTIVE RFID LABELING ON HARD HATS

Hello, in this article, we will tell you about the use of active RFID tags in hard hats and how this issue is used in the field of occupational health and safety. First of all, let’s look at the use of hard hats in occupational safety and the history of hard hats.

USE OF HARD HATS IN OCCUPATIONAL HEALTH AND SAFETY

Research on the root causes of occupational accidents indicates that 79% of accidents are caused by unsafe behaviors and 20% by unsafe situations. When we look at the root causes, unsafe behavior and unsafe situations occur due to ‘human error’. In this context, it can be said that 99% of occupational accidents are caused by human error.

Hard hats are an important piece of equipment for occupational safety. It is vital for people working in mines. Hard hats protect the head as much as possible from stone or rock falls and bumps. In addition, models with helmet lamps are very useful for miners. Those working in constructions, construction sites or shipyards should also wear hard hats. Helmets also provide good protection against weather conditions as they work outdoors. For people working in places such as the iron and steel industry and the industrial sector, wearing a hard hat is essential for safety. Protecting from temperatures up to +50 degrees, hard hats also provide protection against UV rays and electric shocks. While the helmet has gradually evolved into what it is today, it has undergone changes in material, shape and attachments according to needs.

HISTORY OF THE HARD HAT IN OCCUPATIONAL HEALTH

Hard hat used to protect the head area in work accidents; In history, the ED Bullard Company, a family-owned company founded in 1898 by Edward Dickinson Bullard in San Francisco, USA, selling mining equipment. EW Bullard, the son of the company founder, was inspired by the helmet worn by miners in World War I to protect them from hard objects falling on their heads. He patented the helmet in 1919. The question of where the first “helmet use area” was is controversial in the USA. Some researchers say the construction of the Hoover Dam (1931), while others say the construction of the Golden Gate Bridge (1933).

APPLICATION OF ACTIVE RFID LABELS ON HARD HATS

In order to increase the functionality of the helmets, the equipment was enhanced with Active RFID tags. Thus, Active RFID tags, each with a unique identity, were placed on the helmets and integrated with IOT technology. Thanks to the Active RFID tags prepared with software, it is aimed to track personnel and increase occupational safety measures as the main goal.

Thanks to the use of active RFID tags on helmets, personnel can be warned without the need for an authorized person by sending a personal warning or vibration. In undesirable situations encountered in the field, instant notification is made to the authorities determined in the system via e-mail or sms. It can be tracked up to 70-80 meters in open areas, and the software developers of IOT technology continue to work on increasing this distance. The system increases the precautions against work accidents. In the event that the helmet user removes the helmet or the personnel remains immobilized, notification is made via the web base. This system can be preferred to prevent accidents caused by careless employees by preventing unauthorized access to dangerous areas in work areas. Since personnel are tracked, it is possible to determine where and when the employees are located and the personnel can be reached in the field in case of danger. This system shortens the time to intervene immediately in emergencies that may occur and makes a significant contribution to occupational safety by instantly tracking your personnel within the designated areas with precision. The main purpose of the system is to reach the personnel as soon as needed, to increase occupational safety, personnel efficiency and to minimize the damages that may arise due to time losses. The system can be used in many sectors such as shipyards, construction sites, mines, iron and steel industry and industry.

HOW TO SET UP THE SYSTEM?

HARDWARE

It has been developed for systems that you want to control by accessing wirelessly. Personnel can be tracked with signals received from beacon products. They are IOT products that work with Bluetooth technology and are used for personnel tracking or occupational safety. They are placed on the helmet and emit a continuous signal. The signals emitted by the devices are detected by gateways and monitoring is provided.

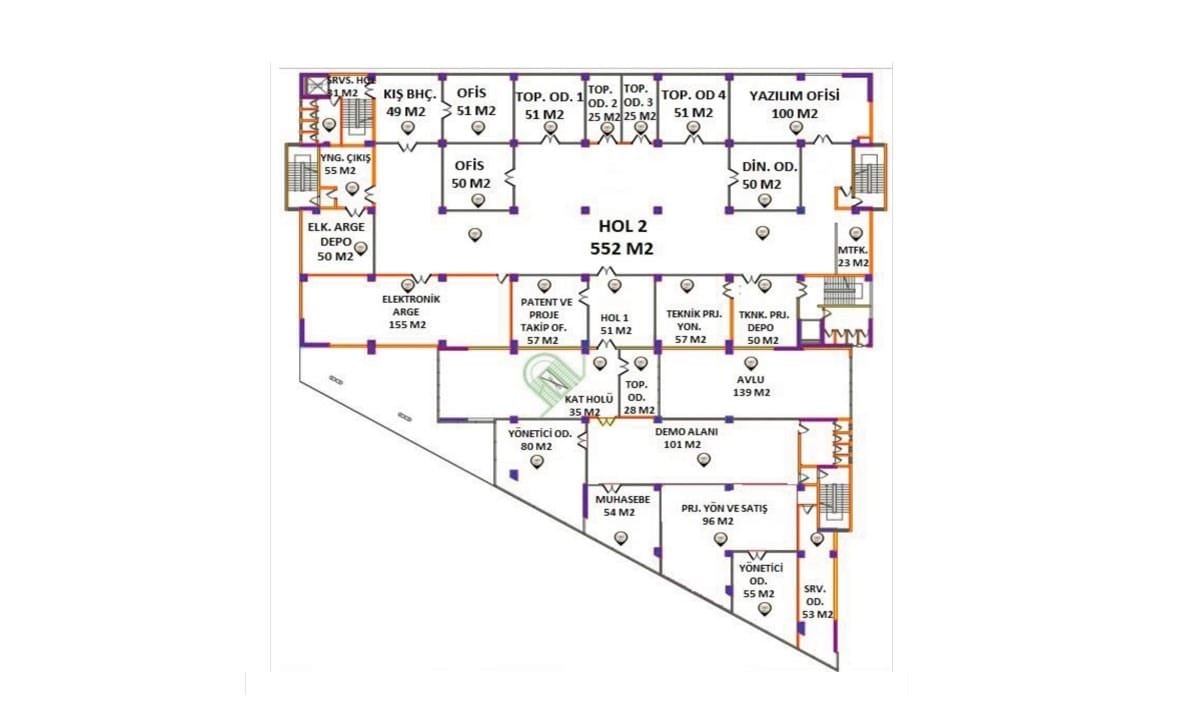

INSTALLATION OF THE SYSTEM IN CLOSED AREAS

Gateways are placed on a room-by-room basis as enclosed spaces are partitioned by restrictors such as walls, glass, etc. As indicated in the sample sketch below, one Gateway per room will be sufficient. In large areas such as HOL 2, the number of gateways can be increased according to the results of the technical examination.

Total Area: 2174 m2

Total Number of Gateways: 29 Adet

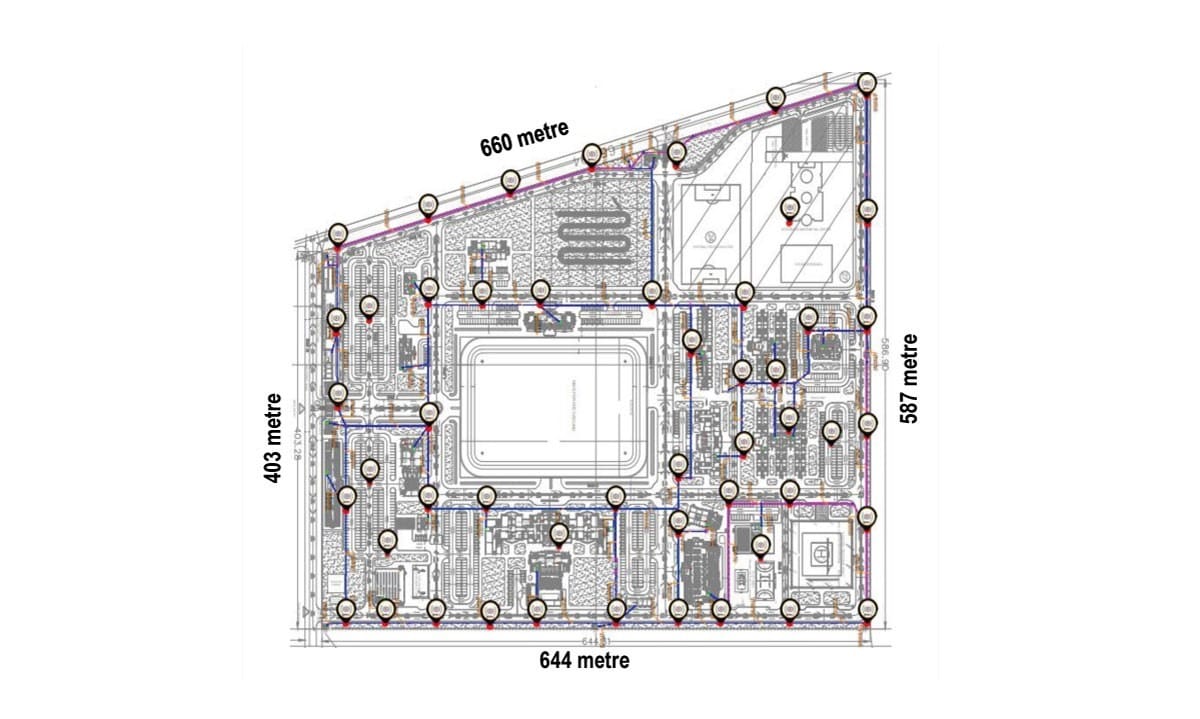

INSTALLATION OF THE SYSTEM IN OPEN AREAS

In open areas, devices can be placed at wide intervals since there are no restrictors such as walls, glass, etc. to prevent the signal reception of Gateway devices.

Total Area: 318.780 m2

Average Distance Between Gateways: 65 -80 meter

Total Number of Gateways: 50 quantity

In this article, we have given information on how we can further increase occupational health and safety measures with hard hats.

You can contact us for detailed information on the subject.